Inspection Process

-

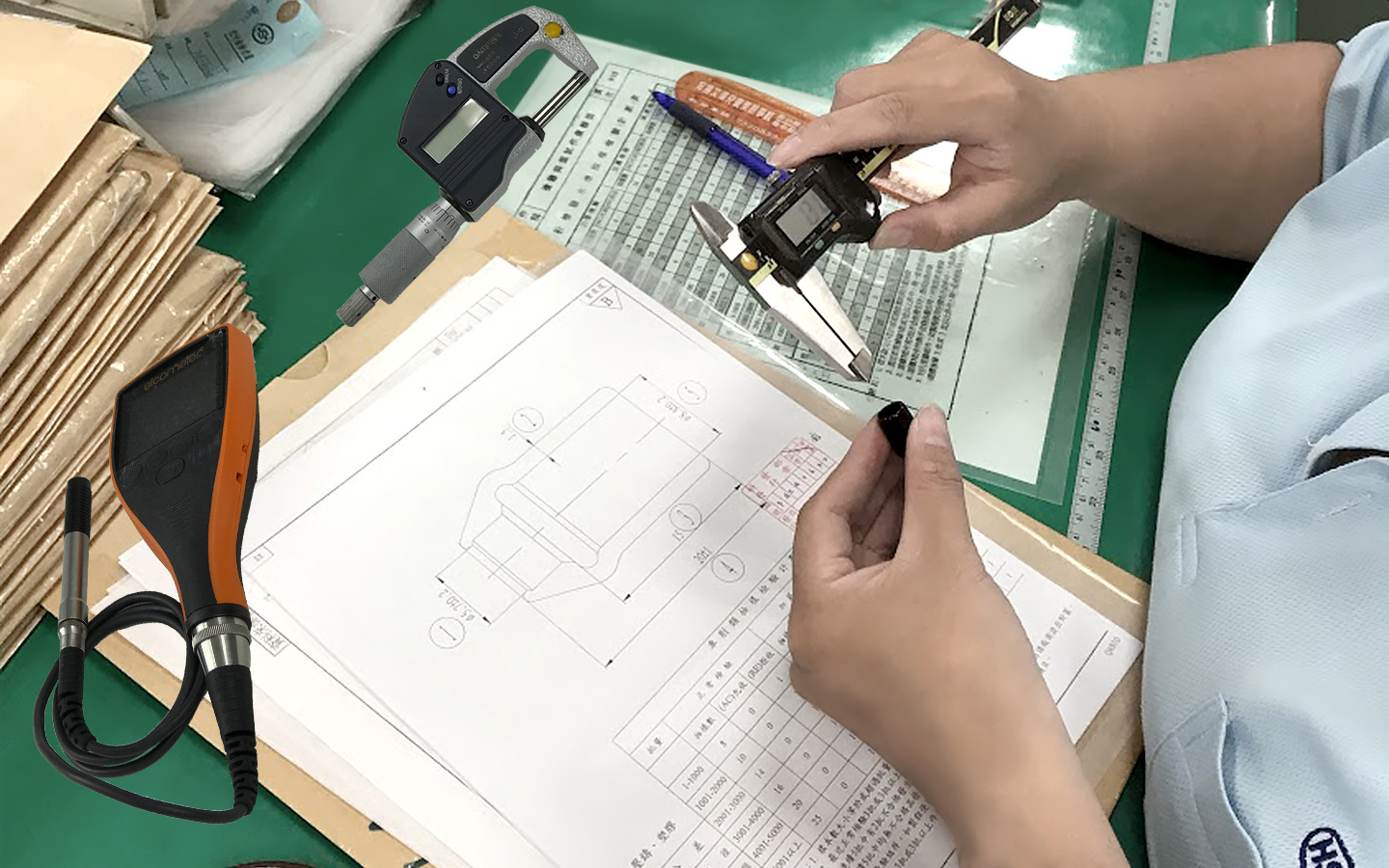

IQC (Incoming Quality Control)

The incoming component from subcontractor will inspect by component drawing, than fill in the result on component inspection standard report for each batch. The sampling quantity was decided by AQL (Acceptable Quality Limit).

-

IPQC (In-Process Quality Control)

According to SOP (Standard Operating Procedure) and carry out self inspection sheet to reach quality assurance in process.

-

Shipment (finished goods) inspection

Carry out assembly inspection standard report for finish goods to reach customer requirement.

-

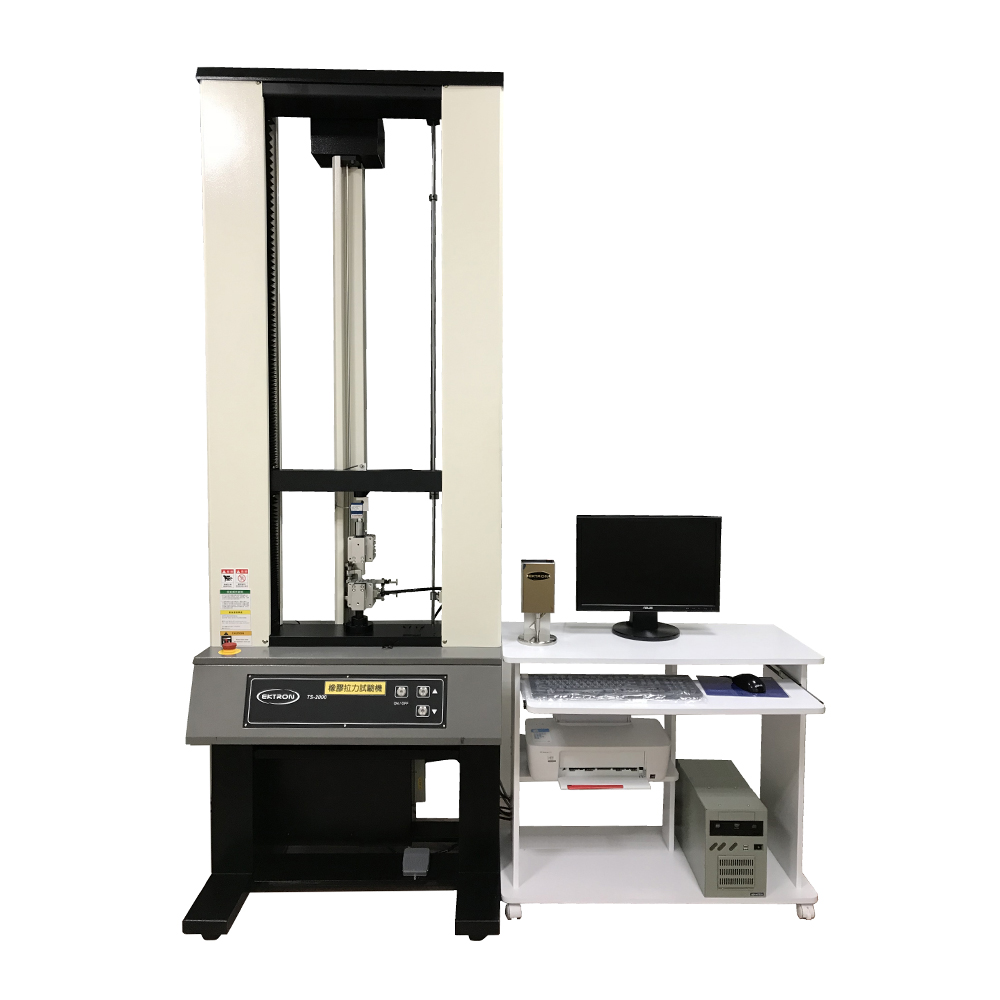

Critical Part Strength Assurance