Leading Push-Pull Cable Manufacturer – Custom Solutions for Your Needs

As a trusted push-pull cable manufacturer, we specialize in designing and producing high-performance push-pull cables, push-pull wires, and complete push-pull cable kits for various industries.

Our cables are engineered for smooth operation, durability, and precision control in applications such as automotive, industrial machinery, medical devices and marine.

Our experience as a top push-pull cable manufacturer ensures we deliver solutions that meet your exact needs.

Custom Push-Pull Cable Design – Engineered for Precision

We provide fully customized push-pull cable solutions based on your specific requirements:

- Length & Dimensions: Designed to fit your exact application.

- Assembly Points & Connectors: Ensuring optimal functionality and ease of installation.

- Performance & Material Selection: Built for strength, flexibility, and corrosion resistance.

- Wide Application: Suitable for automotive, motorcycle, marine, agricultural, and off-road vehicles.

- Industry-Specific Customization: Tailored designs for automotive, industrial, medical, and marine applications.

Push-Pull Cable Layout & Kit Design

We specialize in:

- Push-Pull Cable Layout Design: Optimized routing for efficient and reliable operation.

- Custom Push-Pull Cable Kits: Complete push-pull cable kit assemblies tailored to your needs.

- Mechanical Simulation & Prototyping: Ensuring flawless performance before production.

Why Choose Our Push-Pull Cables?

- High-Quality Materials: Stainless steel, galvanized steel, and other durable materials.

- Smooth & Precise Motion Control: Low-friction push-pull cables for seamless operation.

- Fully Customizable: Length, thickness, fittings, and performance specifications.

- Proven Industry Expertise:Trusted by leading manufacturers across multiple sectors.

Get the Best Push-Pull Cable Solution Today!

Looking for custom push-pull cables, push-pull wires, or a complete push-pull cable kit? As a reliable push-pull cable manufacturer, we’re ready to meet your needs with precision and expertise.

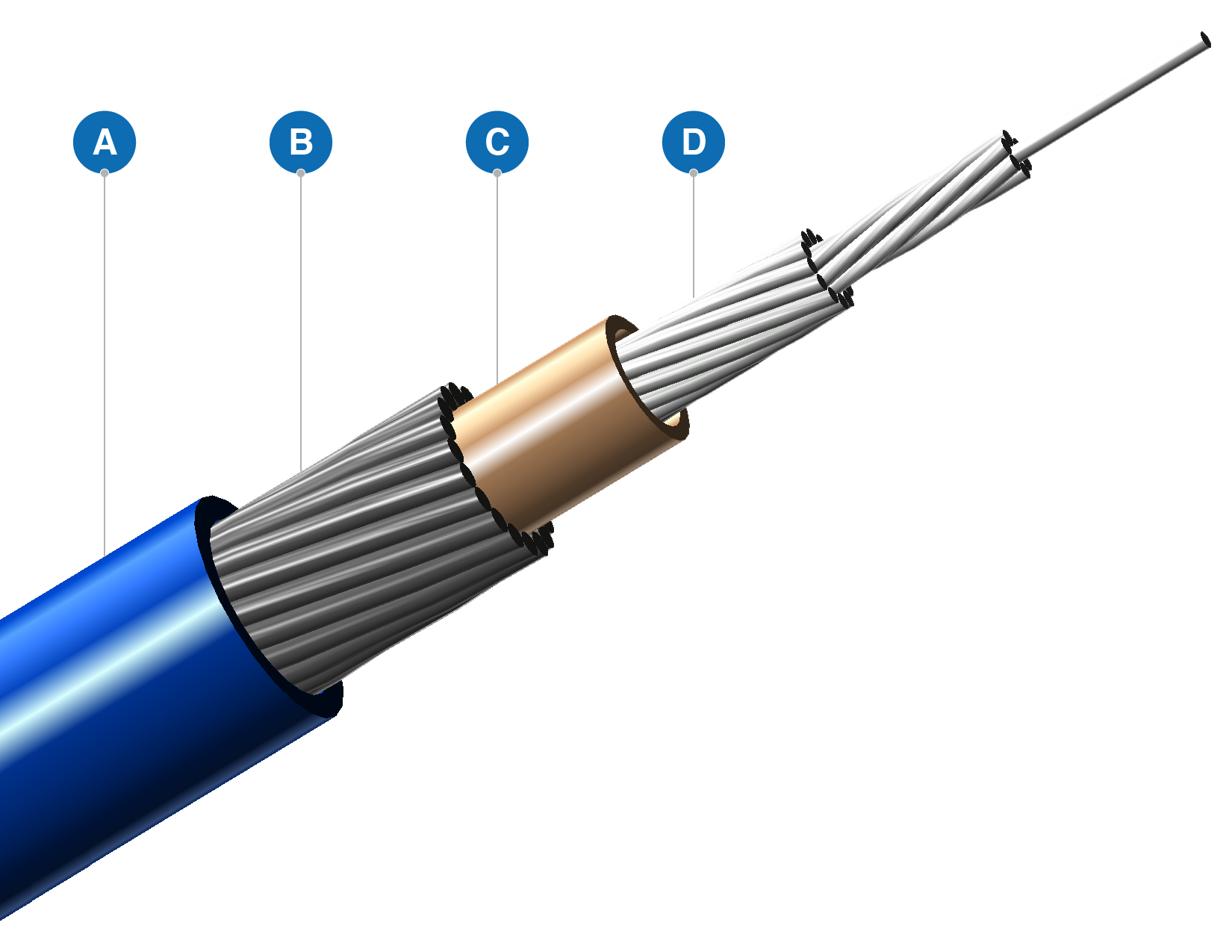

Conduit

| A | Coating Material | PVC | PP | PE | PA6 | TPE | TPEE |

|---|---|---|---|---|---|---|---|

| Coating Operation Temperature | -25°C~80°C | -40°C ~ 120°C | -30°C ~110°C | -40°C ~120°C | -30°C ~100°C | -40°C ~150°C | |

| O.D. range | φ4~16 | ||||||

| B | Stranding Material |

|

|---|

| C | Liner Material | PE | POM | PBT | PTFE |

|---|---|---|---|---|---|

| Liner Operation Temperature | -40°C ~ +80°C | -40°C ~ 120°C | -40°C ~130°C | -40°C ~165°C |

Inner Wire

| D | Inner Wire Construction | 1×19 | 1×N | 7×7 | 7×19 | Armored | OTHER |

|---|---|---|---|---|---|---|---|

|

|

|

|

|

|

||

| Inner Wire Material |

|

||||||