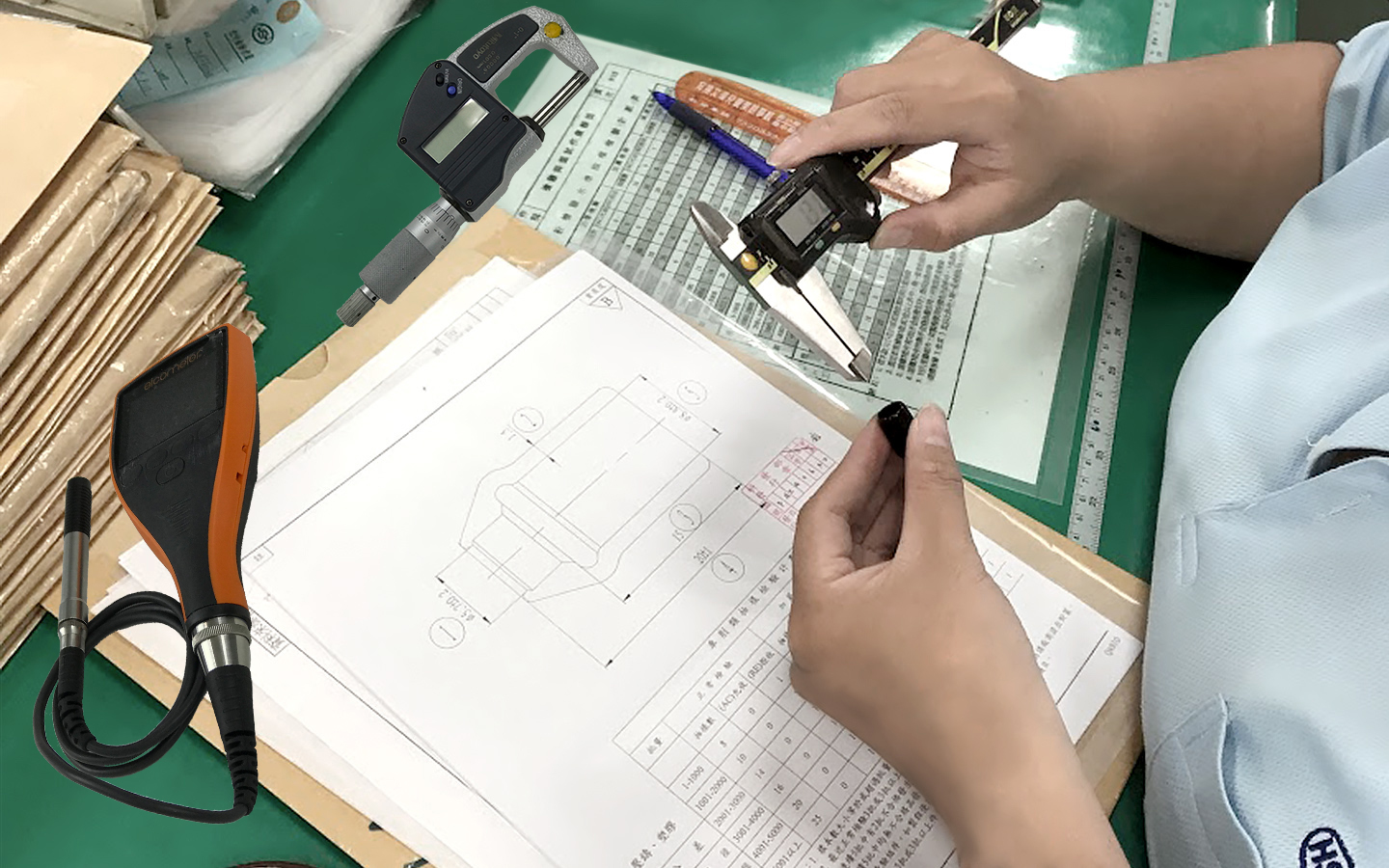

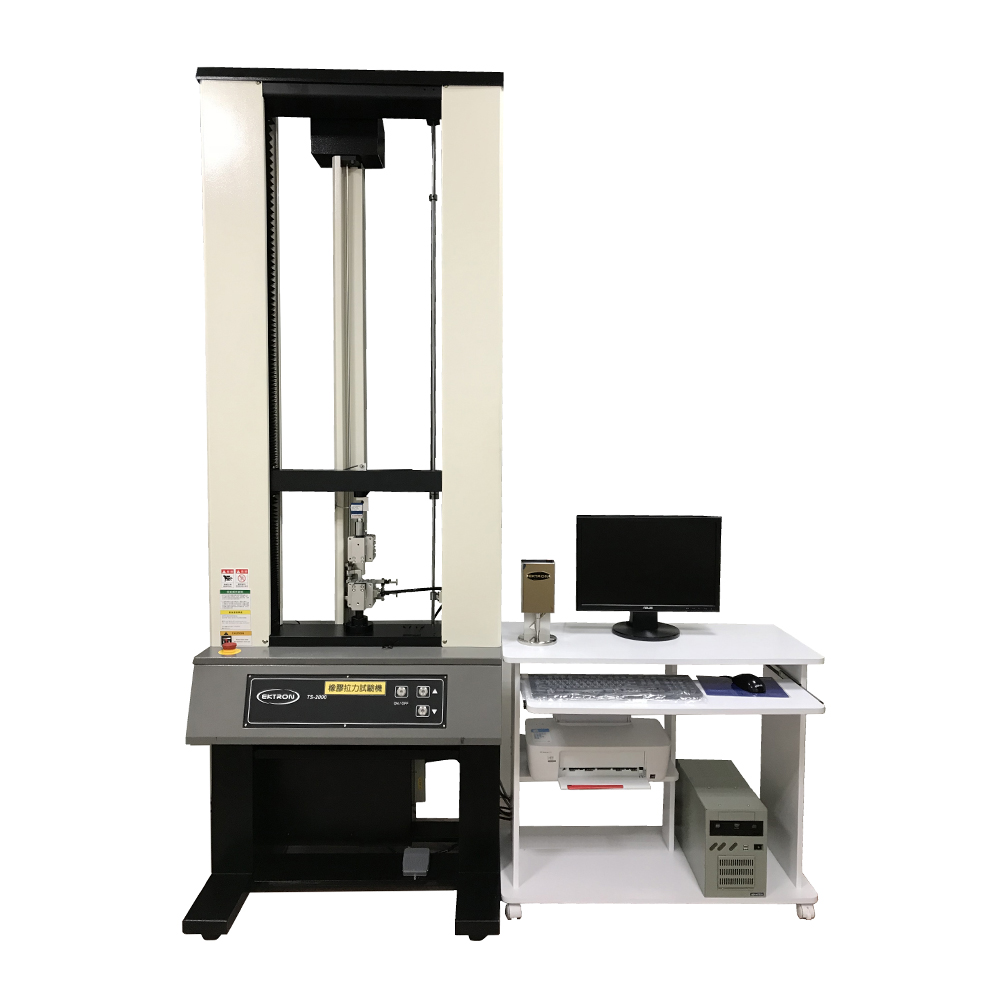

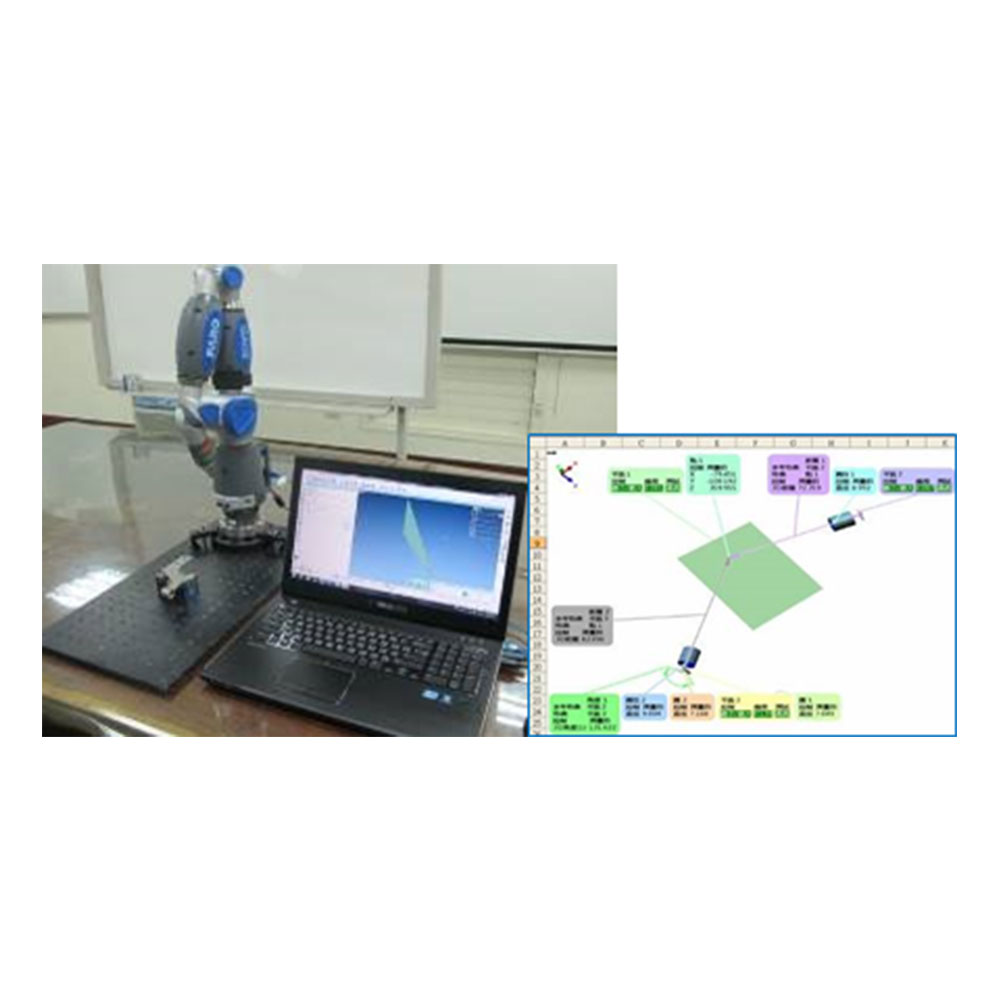

Our guarantee of best quality products lies in the design,

enhanced by well-managed production。

We adopt Quality First belief and it involves the participation of all staff and employees to acquire the end。

The implementation of good quality management is our promise to meet the needs of our customers and acquire their satisfaction。